Managing Change

Economical solutions for environmentally friendly natural slurry management

As a specialist in economical spreading technology and a recognised technology leader in this sector, Vogelsang has been dealing with one crucial question for decades: How can the maximum nutrients be extracted from a minimum of slurry? And that's exactly why we have a range of new products that we would like to introduce to you.

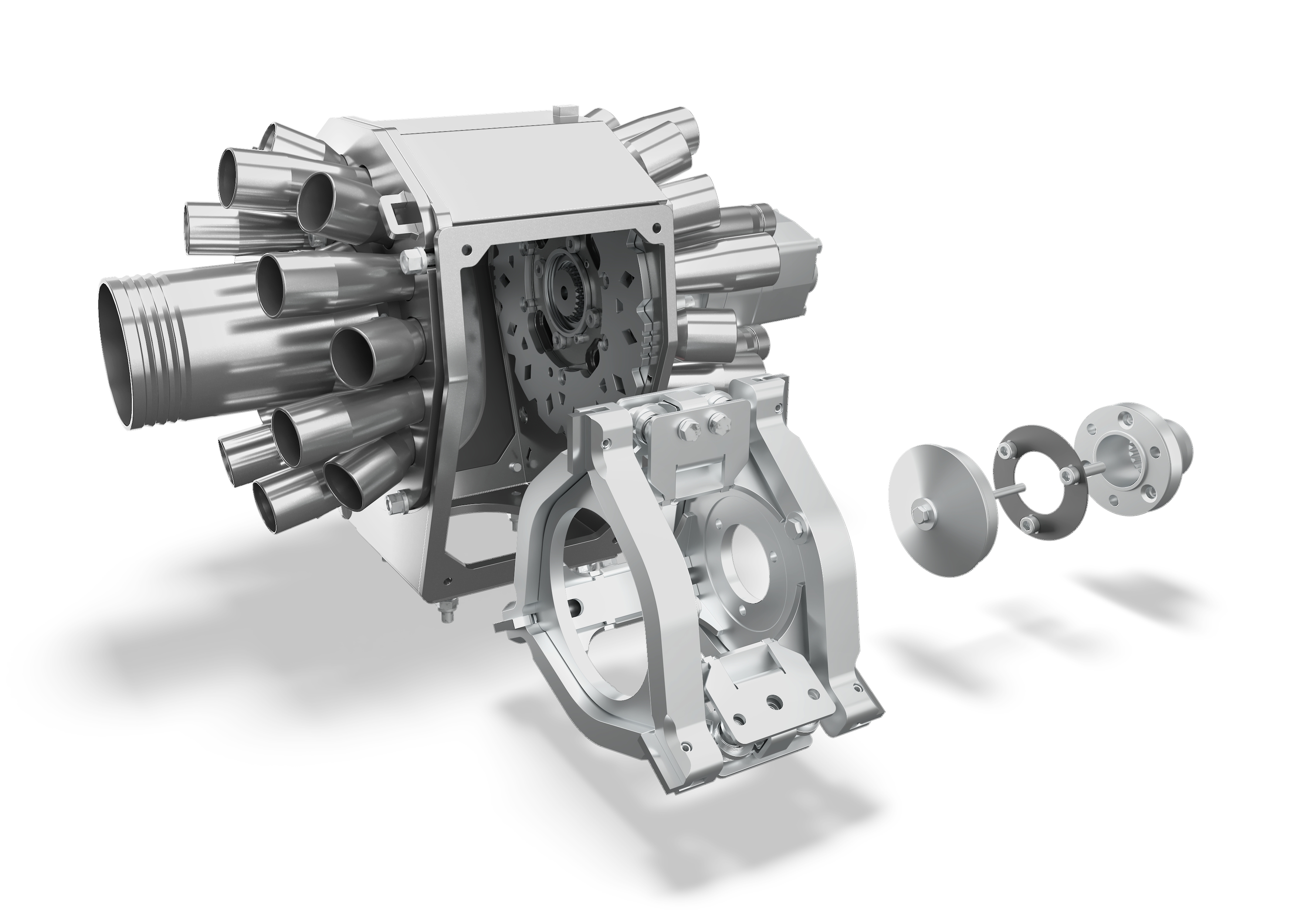

XSplit press screw separator

Make better use of separated slurry

Separation of raw slurry or digestate into a solid fraction and a liquid phase is a long-established process: Separated solid matter can be transported more easily and used, for example, or as bedding material in stables - the separated slurry, on the other hand, can be spread much more easily and more evenly in the field. Thanks to the low fibre content, pumps and precision distributors run smoothly. With the XSplit, Vogelsang is now launching a new high-throughput press screw separator with adjustable dry matter content. With a dry matter content of up to 40%, it is superior to other separators. We can achieve these results by the individually adjustable pressing area and the high-quality elastomer sealing washer. Depending on the medium and consistency, different sieve variants can be used, thus guaranteeing extremely reliable separation results.

ExaCut ECC precision distributor

Runs easily without air

In the past, all precision distributors on the market have been equipped with ventilation hoses and ventilation to guarantee that the slurry flows evenly into the discharge lines. Vogelsang has now succeeded in becoming the first agricultural technology developer in the world to design a precision distributor that does not require any ventilation. The new ExaCut ECC has an innovative rotor concept, which prevents a vacuum from occurring while feeding the slurry evenly into the hose outlets, thus ensuring an even quieter distribution process. The generous cross-sections contribute to the superior smoothness of the new ExaCut ECC. The fact that this even reduces the power and oil requirements is certainly a welcome side effect.

PowerFill Small

Fast filling made easy

Vacuum barrels can be filled up to 30% faster using a turbo filler from the Vogelsang PowerFill series - and with significantly less foam formation than with conventional fillers. This is a fact that enables farmers around the world to fill their tankers quickly and efficiently. At the same time, the pumping process ensures homogenization of the slurry before distribution, which leads to more even spread. The Vogelsang developers have now succeeded in incorporating all of these advantageous characteristics into a turbo filler that weighs 40% less and is extremely compact.

UniSpread 10.5m working width

Universal genius gets wider

Uneven terrain, shorter field lengths, smaller tankers - in many situations it is more economical to use more compact spreading techniques. For even greater flexibility, the UniSpread, which is specially designed for small working widths, can be equipped with both dribble bar and trailing shoe. Thanks to its low weight, its robust frame construction and the high-performance precision distributors, the linkage with a maximum working width of 9 m have quickly established itself internationally - both as a retrofitting solution or in smaller operations. In order to better meet their equipment needs, the UniSpread is now also available with a working width of 10.5 m and automatic end arm folding for an optimum transport width of max. 2.50 m. Variable mounting options at three or four points also allow fast assembly.

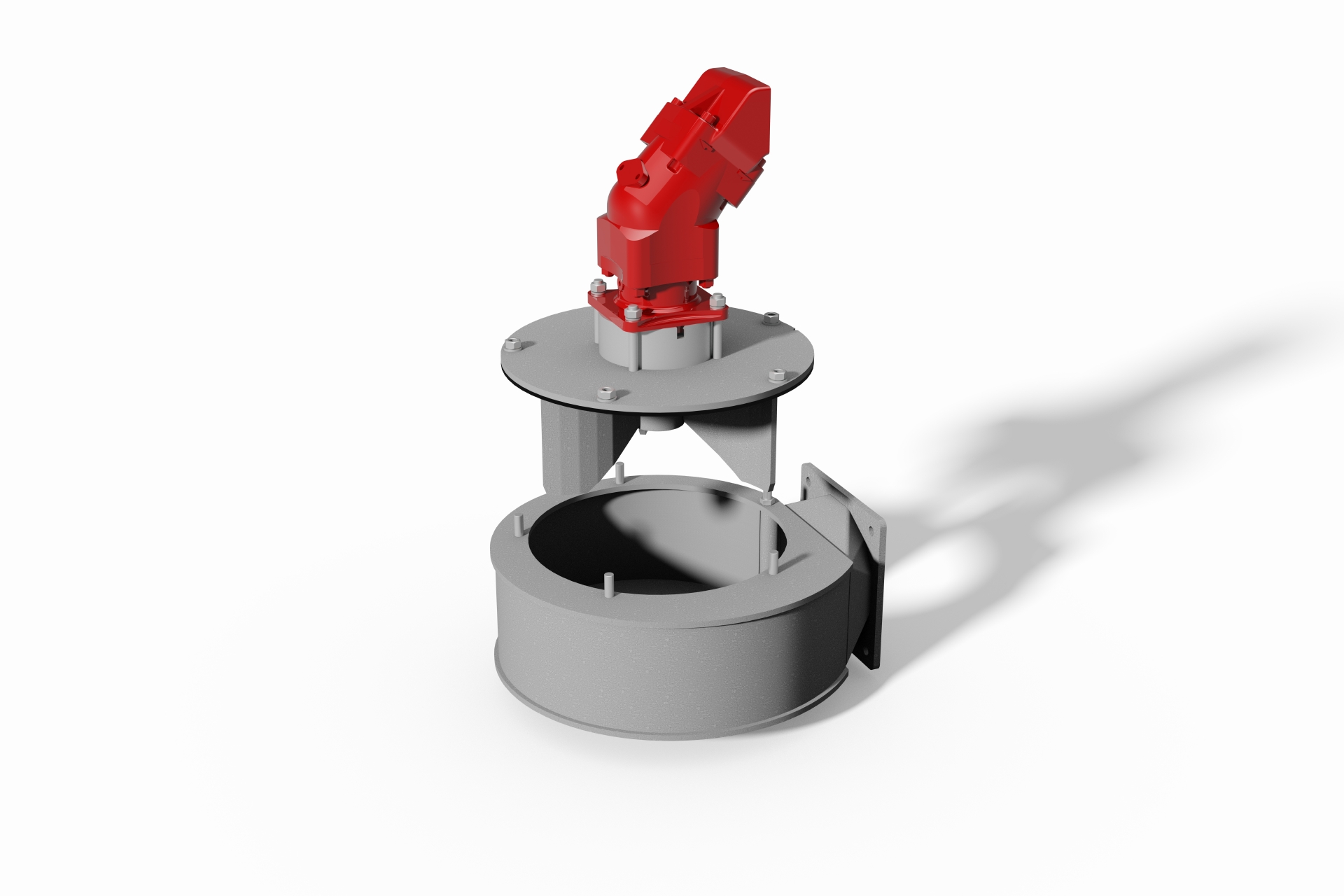

Slurry stabilisation with SyreN

Ready for the future

The SyreN slurry stabilisation system for optimum nutrient utilisation has a new design. New fertiliser restrictions in various countries around Europe and beyond lead to one goal: Reduction of fertilisers with at least the same yield. With its high-precision application technology, Vogelsang has been making a decisive contribution in this area for decades. The potential of the nutrients contained in slurry has been exploited even more effectively since the introduction of the SyreN slurry stabilisation system - a quantum leap, as the system has the same nutrient efficiency as an injection system and operates with significantly more effectiveness. This further reduces the environmental burden, because up to 70% less ammonia emissions are possible.

Flow Performance Monitor for sowing

Knowing that things are working

The ISOBUS-compatible Flow Performance Monitor is used to monitor mineral fertiliser and seed lines. In recent years, sensor technology has been further developed and modified in order to also control the airflow in mineral fertiliser and seed lines on pneumatic seed drills. As soon as there is any clogging, the sensor reports this by indicating the fault directly on the display in the driver's cabin. This enables you to rectify the trouble immediately.